EcooGraphix Full Automatic Thermal Paper Slitting Rewinding Machine

Product Description

Ecoo-1400FA Full Automatic Thermal Paper Slitting Rewinding Machine is suitable for producing ATM Paper, Cash Register Paper, ECG Paper, POS Paper, NCR Paper, Plotter Paper, CAD Paper, SMT Non-Woven, Thin Paper etc.

Specification

| Model |

Ecoo-1400FA |

| Max. Parent Web Width |

1400mm |

| Max. Parent Web Diameter |

1200mm |

| Max. Rewinding Diameter |

300mm |

| Min. Slit Width |

15mm |

| Max. Machine Speed |

300m/min |

| Torque |

100Nm |

| Unwinding Type |

3" air expanding shaft |

| Rewinding Shaft |

0.5", 1" are available (or as your request) |

| Power |

20KW |

| Voltage |

3 phase, 380V, 50Hz |

| Weight |

4000kg |

| Dimension |

5500*2200*1880mm |

Our Advantages

Siemens PLC and MCGS touch control screen, all the parameters can be set on the screen.

Master motor is Siemens Inverter Motor, controlled by Inovance AC drive.

Shaftless unwind stand, hydraulic driven automatic jumbo roll loading.

Ultrasonic web guide for printed paper.

Automatic vacuum core sucker. (Patented)

Upper and lower circular knives shear cutting.

Automatic tucker quickly triggers rewinding.

2 sets loadcell sensor and fully automatic tension controller for constant tension control.

Rotary encoder measures slit length automatically.

90° vertical lay-on roller and banana roller ensures no overlapping problem.

Automatic finishing line: breaker, hammer, and conveyor.

Automatic Hot Shrink Packager (Another packing method available)

Machine Spare Parts

Ecoo-1400FA can produce 23,0000-35,000pcs 57mm x 50mm till roll in 8h, no need dedicated operator.

Core feeding is completed by an automatic core feeder. As long as the plastic core is placed in the bowl in advance, the core feeder will automatically push the plastic core to the core staging conveyor.

Bowl feeder

After the plastic core is pushed to the core staging conveyor, the vacuum core sucker will suck up the core and move it forward to the rewinding station.

Vacuum Core Sucker

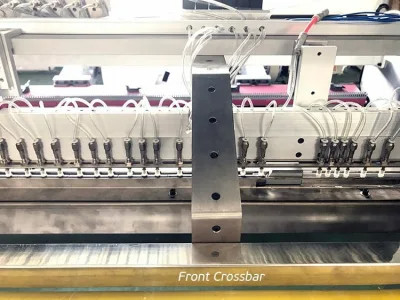

When the core sucker moves forward, the front crossbar pushes the last cycle's till rolls to the finished roll processing station, and these sucked cores are also placed on the rewinding station at the same time.

After placing the cores, the vacuum core sucker moves backward to the initial position, a rider roller presses down on the finished till roll. Then the automatic tail cutting gluing unit cuts off the finished rolls' tail and applies glue, rider roller starts rotating, the glue follows the rider roller's rotation and evenly adheres to the thermal paper's inner layer, and the till rolls are sealed.

Producing And Packaging

More Details

FAQ

1. What are your main products?

We Ecoographix is a specialized supplier of printing machines and consumables. We cover both digital printing and offset printing,

including prepress, pressroom and post press, focusing on packaging printing and book printing.

We have hundreds of users all over the world. We bring forward top quality of Chinese printing products to meet diversified printing requirements.

2. Where is your factory?

Our sale office is in Hangzhou, one hour by train away from Shanghai. Our factories are in Shanghai, Wenzhou, Suzhou and Nanyang.

3. What is your warranty?

One year for machine and printing head if use our ink. One year for machine only if do not use our ink.

4. What is the Lead Time?

Usually 30 days, and we will try our best to meet your demands.

5. What about the Installation and after-sales technician support?

Our engineer can go to help the installation and provide the necessary training. The buyer should take the round air plane tickets and service charge

and the local accommodation cost. Any problems or questions, we will be at your disposal 7x24 hours.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!