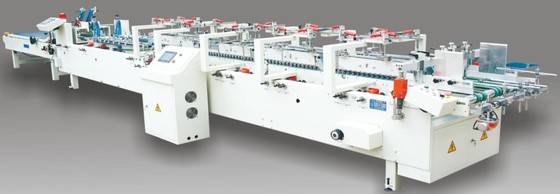

Cardboard Paper Box Making Folding Gluing Machine

Automatic carton folding gluing machine (LG800) is a very stable high-volume machine that can bring more profits to customers.

It has a 4/6 corner function. Each set is controlled by an independent motor. It uses ESC, PLC, imported electronic components, and three-board tracking mode equipment.

Main Features

- The whole machine adopts the structure of laser-cut steel plates.

- Glue-spraying system (three guns and three sensors) optional.

- Inner couriers in the machine are adjusted by motors.

- Plasma system optional.

- Processing data of boxes can be saved in the computer control system (optional).

- Position indicator (optional)

- Variable adjustment.

- Long-distance pre-folding section, 180° folding for the first line, 135°folding for the third line, they are easily open after pre-folded.

Product details:

1. Full cover, bullet train type cover, anti dust, low noise, able to control the temperature by built-in air conditioner.

2. High Speed, Suitable for big orders. Especially for the orders which are more than 50,000 pcs at one time for the same size,

because one line can make around 14000 pcs/ day. Better service for long-term and stable orders

3. Dual-forming stations, box forming has divided into two forming stations, increasing whole line working speed.

4. Pick up box system, can avoid to scraping cover paper, suitable for making high-end boxes

5. YAMAHA Robotic arm

6. Double Germany cameras (1000 pixels)

7. Mitsubishi servo motor

8. Panasonic PLC

9. Anti-leaking gluing system

10.Servo motor feeding system

11. Storage function for the positioning part, easy to adjustment

Application of automatic smart rigid box making machine

Quickly job setting No need to change air pressing plate No need to change tuck in blade No need to move camera for size changing, quick job changing Make high-end boxes Special pick up and wrapping system Can use the carton paper to wrap the inner box Can make big size box, such as 600*400mm, and the height can reach 120mm Storage(memory) function for sizes setting Suitable for changeable orders Such as 10,000 pcs for one order.

Feeder

- MIKI-pulley infinite speed variator 1/set.

- Independent adjust feeding belt, ensure the smoothly paper feeding.1set/6pcs,size: 1026*30*8mm

- Independent motor, inverter adjust speed, effectively ensure the balance of paper spacing.

- Paper carry rod with high performance Taiwan-made vibrating motor.

- Air feeding device.(optional)

Alignmentunit

- Aligning the askew paper wihch from feeder, make sure the paper running in straight line.

- Alignment unit can be adjusted up and down, suitbale for different thickness paper stably.

- correct the paper, avoiding the paper going to two sides.

Two belts: 2145*34*4mm

Pre-folding unit

- 2 plate conveyor belt structure, segmenting left and right upper belt plate can be adjusted according to product demand, fast and efficient.

- three long top courier in this section, 180 degree folding could be preformed

Nitta belts :1 set

specifications:1985*24*3mm-2pcs 3375*24*3mm-2pcs

5000*44*4mm-1pcs 5000*24*4mm-1pcs 4755*30*4mm-1pcs

Crash-lock unit

- 3 plate conveyor belt board structure, segmental upper belt board function is the same as the prefolding part, eliminate the problems in the production of special-shaped box products effectively.

- The upper and middle belt board is detachable, depending on product requirements for disassembly and debugging.

- Nitta belts 1set /9 pcs

specification:

1985*24*3mm-2pcs 3375*24*3mm-1pcs

1780*24*3mm-2pcs 3450*24*4mm- 3pcs

3610*30*4mm-1pcs

Gluing unit

- The mechanical lower pasting cylinder is designed with separate type of rubber wheel and rubber cylinder, high speed, easy to clean and maintain.

- Crashlock, 4/6 corner box ,etc need to equip eletrical spray guns. (recommend 3 or more guns)

- width of gluing wheel 4MM (standard), other width could be customized

| Main motor |

Paperboard |

Corrugated |

Max linear speed |

Weight |

Machine size |

| 11KW |

180-650gsm |

Flute E.N.F |

400m/min |

5000KG |

1500×220×190cm |

| Total power |

Power supply |

Loading Container |

|

|

| 19.5KW |

380V AC3F 50Hz |

40GP+20GP |

|

|

Shipping And Packaging

| Shipping |

By sea, or as your requirement to do |

| Packaging |

By Strong Wooden Case |

| Packaging Dimensions |

Case 1 |

Size: 2980mm* 1560mm* 1320mm |

| Net weight : 1500KG |

| Gross weight: 1600KG |

| Case 2 |

Size:1310mm*1170mm*900mm |

| Net weight :250KG |

| Gross weight:290KG |

FAQ:

Q:Why choose us ?

A: We are manufacturer .We have strict QC policy to control the producing process,strong technica team and after-sales service team to offer best support,try our best to exceeding your expectations.

-Inquiry will be replied with 24 hours.

-OEM service is available.

-Protect your design & information.

Q:Do you have the CNC workshops ?

-We have our own CNCworkshops,we produces the molds by ourselves.

Q: Can I have sample before order?

A: Yes ,free samples can be sent out,the freight cost is paid by you.

(1).You can provide your a/c like DHL/Fedex/TNT ect.

(2).You can call your courier to pick up at our office.

(3).You can pay us the freight cost by T/T.

Q: Can you make the customized paper cone ?

A: Yes , please show us your sample first .

Q: What time for delivery ?

A: Machine about 45 days after get your deposit.

Q: Engineer oversea service ?

A: Yes ,we can send engineer to help you install ,training worker until the machine normal running.

-If you meet any problem at any time,we could offer the technical support on line as well.

Q: What payment term ?

A: T/T 30% down payment ,balance before delivery ,or LC at sight or D/P etc.

Q: Do you have any certificates?

A:We have CE and ISO certificates .

Q: Where is your factory located ? How can I visit you?

A: Our factory is located at Wenzhou city ,Zhejiang province .We can pick you up from either Wenzhou airport or Shanghai airport or Wenzhou station by high-speed rail.

Q:How can I contact you ?

A:You can contact us by Email / Whatsapp / Wechat / Telephone .

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!