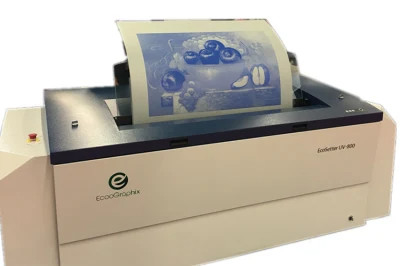

Thermal CTP Machine For Offset Printing Prepress CTP Plate Making

1. Application

EcooGraphix Thermal CTP(Computer To Plate) Plate making Machine is the first Prepress necessity of quick short-run offset printing. It can output the images on the computer to printing CTP plate directly through the CTP machine and save the film and labor.

EcooGraphix T400series thermal CTP are for A1, A2 or B2 paper size newspaper or commercial printing with the output speed 16PPH to 28PPH. The CTP is operated by manual, very easy to use.

By EcooGraphix CTP, the customer can get excellent output image quality, highly reliable stability, less space occupied with more flexibility.

2. Characteristic

Maximum size of plate: 800×690mm

Features: Small Volume, high stability, and perfect output quality.

UV plate and thermal plate are available for you to lower production cost.

3. Specifications

|

ECOO T-400 Series Thermal CTP Specifications

|

| Model |

T-400F |

T-400S |

T-400E |

| Exposing Method |

External Drum |

| Imaging System |

48-channel |

32-channel |

24-channel |

| |

Discrete 830nm laser diode |

|

Throughput

|

28 plates/hour

|

22 plates/hour

|

16 plates/hour

|

| |

800mm x 660mm, 2400dpi |

| Plate Sizes |

Max. 800mm x 690mm

Min. 400mm x 300mm |

| Media Type |

Positive 830nm thermal CTP plate |

| Plate Thickness |

0.15mm to 0.30mm |

| Resolution |

2400dpi |

| Repeatablity |

±5μm(Continuous exposing for 4 times or above on the same plate with

a temperature of 23℃ and humidity of 60%)

|

| Interface |

USB 2.0/ USB 3.0(USB 2.0 is recommended) |

| Plate Loading |

Manual |

| Net Weight |

800 KG |

Machine Size

(WxLxH)mm |

1900 x 1200 x 1000 |

| Power Supply |

Single phase: 220AC, +6%, -10%, Power Consumption: 4KW |

| Environment |

Recommended: 21-25℃, Max. 15-30℃, Humidity: 40-70% |

4. Major Highlights

1) Superior dot quality reproduction proven by worldwide market: 1%-99% dot reproduction. Up to 250lpi screening, 2400 dpi or 1200dpi optional.

2) Fully qualified: for any thermal non-process plate and process plates.

3) Robustness and simplicity: robust machine and easy to use. User friendly and simple design to avoid human error.

4) Worldwide top class components and parts supplied by international well known suppliers from Japan, USA and Germany.

5) Long lifetime and warranty of parts: laser diodes lifetime at more than 10,000 imaging hours. (approximately 20,0000 plates)

6) Long warranty of the machine: 3 years warranty (free replacement of all parts)

Low Cost of Parts: after 3 year warranty, very low cost of parts. For example, laser diode at US$250 per piece.

7) Guaranteed Service: installation and training conducted by technical engineer from factory, ensuring best setup and training to be achieved. Regular remote maintenance to be conducted every 2 months. Proactively revisit by engineers to be conducted. 7x24 hours service response.

8) Proven Worldwide market leader:

Over 6000 units have been installed worldwide over the past 10 years.

USA and Canada: Over 50 units in USA and Canada in last 3 years by leading US press manufacturer.

Turkey: 35 units installed in Turkey by Esen Graphics.

Installations in other countries

UK, Italy, Spain, Hungary, Russia, Mexico, Brazil, Colombia, Ecuador, South Africa, Nigeria and etc.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!