CTP Printing Plate Making Machine Software Parts RIP Workflow

for offset commercial or newspaper printing

1.Application

The Express RIP offers performance, productivity and flexibility to prepress, workflow and modern day digital devices. It can seamlessly integrate with Compose’s workflow and output solution. It is developed to provide you with an impressive line-up of advanced screening, trapping and colour management for increased efficiency. It’s the ideal RIP engine to use across all your prepress and printing operations!

2.Characteristic

Comprehensive range of output devices supported

Supports over 200 output devices such as imagesetters, platesetters, large format inkjet plotters and laser printers from major manufacturers.

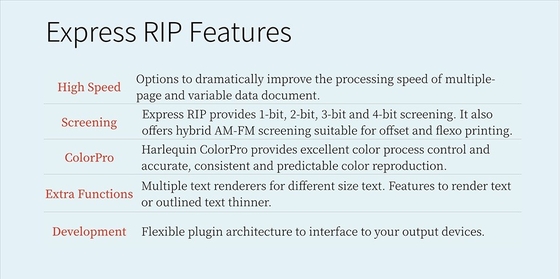

Colour management

Express RIP provides excellent colour control to ensure consistent, accurate and predictable colour reproduction. Users can create ICC profiles using ColorPro or can use pre-configured ICC profile plug-ins that Compose has developed for a variety of devices.

Overprints control for white and varnish

New configuration features to allow opaque white colorants or varnish to be overprinted correctly as your design intended i.e.

colorants should never knock out specified colorants (such as varnish) or specific colorant (such as white or certain metallic) should never be knocked out by other colorants.

Forcing black knockout

The existing black overprint now comes with a new option to force pure black objects to knock out in order to improve legibility particularly in small text in digital presses.

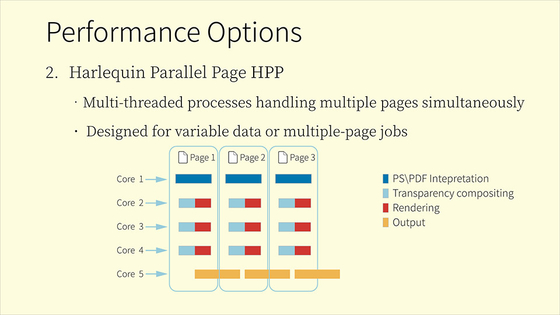

Harlequin Parallel Pages (HPP)

HPP option allows the RIP to process one page while it’s still rendering the previous one. It greatly extends multi-threading support, allowing maximum use to be made of both workstation and server-grade multi-core CPUs.

Harlequin VariData (HVD)

HVD greatly accelerates the processing time of regular PDF files containing variable data including not only, PDF/VT files. HVD intelligently recognizes variable data and static backgrounds in personalized print, direct mail and transpromo jobs, thus greatly accelerates processing time of these complex variable data jobs.

1. Specification

Model: EcooSetter UV-400S CTcP

Laser wavelength: 400-410nm

Plate: UV plate, high-sensitive PS plate

Exposing Method: External Drum

Imaging System: 32-channel

Throughput: 22 plates per hour, 800mmx660mm 2400dpi

Plate Size: Max. 800x690mm min. 400x300mm

Plate Thickness:0.15mm to 0.3mm

Resolutions:2,400dpi, 1200dpi optional

Repeatability:±5μm(continuous exposing for four times or above on the same plate with a temperature of 23ºC and humidity of 60%)

Interface:USB2.0

Weight:800KG

Size:1900×1200×1000mm(W×D×H)

Power Supply:Single-phase: 220AC+6%,-10%;Power Consumption:4KW

Environment:recommended: 21-25ºC,max.18-26ºC,humidity:40-70%

2. Other Similar Models:

| Model |

UV-800F |

UV-800S |

UV-800E |

UV-400F |

UV-400S |

UV-400E |

| Exposing Mothod |

External Drum |

| Imaging System |

64-channel |

48-channel |

32-channel |

48-channel |

32-channel |

24-channel |

| |

Discrete 405nm laser diode |

| Throughput |

28plates/hour |

22plates/hour |

16plates/hour |

28plates/hour |

22plates/hour |

16plates/hour |

| |

1030mm x 800mm, 2400dpi |

800mm x 660mm ,2400dpi |

| Plate Sizes |

Max.1163mm x 940mm

Min.400mm x 300mm |

Max.800mm x 690mm

Min. 260mm x 300mm |

| Exposing Size |

Max.1160mm x 934mm

Min.260mm x 284mm |

Max.800mm x 646mm

Min. 260mm x 284mm |

| Media Type |

positive UV-CTP plate with sensitivity ≤75mj/cm2 |

| Plate Thickness |

0.14mm to 0.30mm |

| Resolution |

2400dpi,1200dpi optional |

| Repeatablity |

±5μm(continuous exposing for 4times or above on the same plate with a temperature of 23ºC and humidity of 60%) |

| Interface |

USB 2.0 |

| Plate Loading |

semi automatic |

| Net Weight |

900kg |

800kg |

Machine Size

(WxLxH)mm |

2330x1050x950 |

1900x1200x1000 |

| Power Supply |

single phase:220AC,+ 6%,- 10%, power Consumption:4KW |

| Operation Environment |

recommended:21-25ºC, Max.18-26ºC, humidity:40-70% |

3. Major Highlights of EcooGraphixT-800 thermal CTP

1) Superior dot quality reproduction proven by worldwide market:

1%-99% dot reproduction

Up to 250lpi screening ,2400 dpi or 1200dpi optional

2) Fully qualified: for any thermal non-process plate and process plates.

3) Robustness and simplicity: robust machine and easy to use. User friendly and simple design to avoid human error.

4) Worldwide top class components and parts supplied by international well known suppliers from Japan, USA, and Germany

5) Long lifetime and warranty of parts: laser diodes lifetime at more than 10,000 imaging hours. (approximately 20,0000 plates)

6) Long warranty of the machine: 3 years warranty (free replacement of all parts)

Low Cost of Parts: after 3 year warranty, very low cost of parts. for example, laser diode at US$250 per piece.

7) Guaranteed Service: installation and training conducted by technical engineer from factory, ensuring best setup and training to be achieved. Regular remote maintenance to be conducted every 2 month. Proactively revisit by engineers to be conducted. 7x24 hours service response.

8) Proven Worldwide market leader: (Some highlights installations)

Over 6000 units installed worldwide over past 10 years

USA and Canada: Over 50 units in USA and Canada in last 3 years by leading US press manufacturer.

Turkey: 35 units installed in Turkey by Esen Graphics

Installations in other countries UK,Italy,Spain,Hungary,Russia,Mexico,Brazil,Colombia,Ecuador,South Africa,Nigeria and etc.

FAQ:

Q1. What are your main products ?

Our main products are the Prepress 4up and 8up Online/Offline Thermal CTP , CTCP , VLF CTP and CTCP, Flexo CTP , Processor , Offset Plates ,inks , blankets , postpress Packing equipments and so on.

Q2. Where is your factory ?

Our CTP machine factory is located in Hangzhou city , which is about 1.5 hour by train from Shanghai.

You are warmly welcomed to visit our factory!

Q3. What is your warranty for the CTPs ?

Three years' Laser Head and main spare parts for the CTPs, One year for the Processor.

Lifetime Warranty for CTP machine and CTP plate.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!