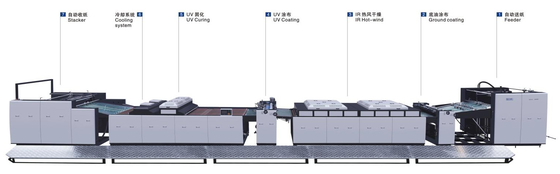

UV Varnish Full Overall Coating Machine Ecoo-2000A

The ECOO 2000A series is a practical fully automatic coating machine developed by our company, which is suitable for posters, books, brochures, color boxes, color box packaging, handbags, etc.

Features:

1:Paper pre-stacker,to realize non-stop paper feeding and receiving

2:High degree of intelligence, one-button start and acceleration, more convenient and efficient than traditional segmented control.

3:The shaft head is 55mm large, which is more stable and firmer than the traditional 35mm under high speed, without deformation, and good coating effect!

4:Synchronous belt transmission, the equipment is more stable, no jitter. The surface texture effect will be better in high-end products.

5:The oil guard has high precision, and it is more difficult for water to enter the bearing than the traditional one.

6:The air knife is easy to operate! High-precision correction, tight on both sides, no slight soft deformation and damage to the mesh belt.

Remarks:

Coating speed depend on paper weight, film thickness and gule material quality.

Subject to change without notice.

Standard Configuration: Selectable Configuration:

Auto Feeder

Multifunctional Coating Unit

UV Curing System

Auto Delivery Unit

Auto Control

| High Speed Coating Machine |

| Model |

Ecoo 1200A |

Ecoo 1200A-2L |

| Max.sheet size |

1200*1000mm |

1200*1650mm |

| MIN.sheet size |

300*300mm |

300*300mm |

| Sheet thickness |

80~450g/m2 |

80~500g/m2 |

| Production speed |

0~80m/min |

0~80m/min |

| UV Lamp |

3pcsx9.75Kw |

3pcsx9.75Kw |

| IR Lamp |

18pcsx1.5Kw |

18pcsx1.5Kw |

| Paper feed heigh |

1100 |

1100 |

| Paper stack height |

1050 |

1050 |

| Weight |

65000kg |

67000kg |

| Dimension |

12500x2050x2000mm |

13500x2050x2000mm |

| Power |

50Kw |

50Kw |

| Remark: Production speed depending on sheet weight, size and quality |

1.Auto feeder

Adopt high-speed offset press feeder (12000 sheets/hour) to ensure fast and stable operation.

Paper photoelectric control, automatic lifting.

Double protection feeder lifting safety.

Using the latest paper stacker design, the entire tray can be pushed in, and the tray can be pushed in directly after printing, without manual paper sorting.

Pre-stacker can also be used. two-way choice. Greatly save paper time and reduce the labor intensity of operators.

2. Coating Unit

Using cast iron body, strong rigidity and long life.

Three-roll reverse coating.

A:The thickness of the oil varnish can be controlled by adjusting the metering roller speed to save oil.

B:A separate frequency converter controls the reversal of the metering roller, which has more frequency converters, motors, reducers and other configurations than the traditional roll-to-roll coating.

C:Iron roller 130MM adopts chrome-plated mirror surface treatment, rubber roller 165MM adopts 60 degree polyurethane rubber roller. The larger the roller, the thicker the rubber, ensuring fine coating and no orange peel.

Equipped with an air knife, it can make 80G thin paper, the size of the wind, and the time of blowing are controlled by PLC.

Automatic stop function for roll paper.

Automatic counting function.

The rollers are adjusted synchronously, driven by the synchronous belt to make the coating effect stable and great.

Equipped with two oil tanks, UV and IR, and equipped with temperature heating control to ensure that the UV oil is coated between 40-60 degrees.

The gap between the coating roller and the pressure roller of each machine head is adjustable from 0-50mm.

The main rollers adopt 55-diameter shaft heads and heavy-duty bearings, which greatly extend the life of the bearings.

The diaphragm pump is used for oil supply, no motor is needed, and the operation is safer.

Double scrapers and a unique bottom roller automatic cleaning system, double oil pan device, the lower roller is immersed in the small oil pan when working, which can effectively clean the lower roller and prevent the oil from drying during shutdown.

3.IR drying and UV curing

- The better the leveling of the oven, the stronger the drying and curing.

- Equipped with UV and IR systems, which are controlled separately and cannot be used at the same time.

- 27 IR lamps and 3 UV lamps, IR lamps generally have a life of 2 years, UV lamps have a life of 800~1000H, and transformers have a life of more than one year .

- The UV part adopts 8-12KW adjustable electronic light source, which has greatly improved safety performance than the traditional voltage source light source.The light source can adjust the brightness automatically as the change of machine's running speed, which can be changed from 30% to 100%. Thus the average energy consumption is saved by more than 30%.

- Emergency stop or overheat protection device, when the emergency stop or the temperature inside exceeds 150 degrees, the protective cover will automatically rise to dissipate heat to prevent fire

- Equipped with a ventilation system, under the UV curing box, there is a strong suction device composed of an exhaust fan and a wind box, which can extract ozone, dissipate heat and make the paper not easy to curl in the furnace, but can pass smoothly.

- Equipped with automatic correction system, (double correction, double over-limit protection). The paper conveying adopts the imported Teflon conveyor belt, which can prevent ultraviolet rays, is strong and durable, does not support the paper, the electric eye detects the Teflon conveyor belt, and the automatic homing correction device

- The whole process of suction to ensure that the coating products will not float and do not pile up paper. The oven is equipped with iron wire protection to prevent the paper from floating on the paper and cause a fire.

4 Cooling system

- After the paper dries out, it is quickly air-cooled to make the paper dry faster without anti-sticking.

5 Automatic delivery system

- Paper photoelectric control, automatic lifting

- Double protection feeder lifting safety

- Equipped with pneumatic paper flap function, you can set the number and time of the paper beat to ensure neatness

- Disorderly paper automatic lowering function

6 Power dusting device(optional)

- Adopting the water powder removal method, the powder removal efficiency reaches 75% without damaging the paper. The body is made of high-quality cast iron to ensure accuracy.

The bottom oil head adopts three-roller coating and adopts synchronous belt wheel transmission to improve transmission efficiency and reduce coating lines.

- Increase the coating effect without scratching the paper

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!