1. Adopt 256-channel laser light valve;

2. The output speed reaches up to 35-55plates/hour for 8 up plate(1,030×800mm, Plate sensitivity: 100mJ/cm²), two times faster than former devices;

3. With square screen imaging technology adopted, reach saturation increasing by 21% and fineness and precision ten times higher than original;

4. With linear motor high-precision positioning equipped, achieve longer service life and lower operation and maintenance cost for customer.

| Model |

F |

V |

X |

| Exposing Method |

External Drum |

| Imaging System |

825nm laser |

|

Throughput

|

35plates/hour |

45plates/hour |

55plates/hour |

| 1030mm x 800mm, 2400dpi, Plate sensitivity 120mj/cm² |

| Plate Sizes |

Max.1163mm x 940mm

Min.400mm x 300mm |

| Plate Thickness |

0.15mm, 0.30mm |

| Resolution |

Standard: dual resolutions 2400dpi and 1200dpi or optional 2540dpi and 1270dpi. Variable high resolution option: maximum up to 10000dpi at fast scan direction |

| Repeatability |

0.01mm |

| Interface |

Optical Fiber |

| Plate Loading |

Standard: Simplified Autoloader or multi-cassette Autoloader(four cassettes) |

| Punching System |

Optional: internal punching(maximum four sets of plate holes) |

| Net Weight |

CTP: 1200kg, Simplified Autoloader: 200KG, Multi-cassette Autoloader: 570KG |

Machine Size

(WxLxH)mm |

1900x2370x1320 |

| Power Supply |

CTP(single phase:220V, Max power(Peak Value): 4KW)

Simplified Autoloader(single phase:220V; Max power(Peak Value): 900W))

Multi-cassette Autoloader(single phase:220V; Max power(Peak Value): 1100W))

|

Operation

Environment |

recommended:21-25℃, allowable temperature: 15-30℃,relative humidity:40-70% |

| T-400 QS Thermal CTP Machine with Single Cassette Autoloader Specification |

| Model |

T-400QS |

| Exposing Method |

External Drum |

| Imaging System |

825nm laser |

|

Throughput

|

25plates/hour |

| 800 x 660mm, 2400dpi, Plate sensitivity 120mj/cm² |

| Plate Sizes |

Max.800mm x 660mm

Min.300mm x 300mm |

| Plate Thickness |

0.15mm, 0.30mm |

| Resolution |

Standard: 2400 dpi or 1200 dpi |

| Repeatability |

0.01mm |

| Interface |

Optical Fiber(Fiber-way) |

| Plate Loading |

Standard: single cassette autoloader with manual plate insert function |

| Inline punching System |

Optional: internal punching (maximum four sets of plate holes) |

Machine Size

(W x Lx H)mm |

1450x1950x1290 (additional 600mm length for conveyor to wash unit) |

| Power Supply |

CTP(single phase:220V, Max power(Peak Value): 4KW)

Simplified Autoloader(single phase:220V; Max power(Peak Value): 900W))

Multi-cassette Autoloader(single phase:220V; Max power(Peak Value): 1100W))

|

Operation

Environment |

recommended:21-25℃, allowable temperature: 15-30℃,relative humidity:40-70% |

2. Major Highlights of EcooGraphixT-800 thermal CTP

1) Superior dot quality reproduction proven by worldwide market:

1%-99% dot reproduction

Up to 250lpi screening ,2400 dpi or 1200dpi optional;12800DPI is available upon requirement;

2) Fully qualified: for any thermal non-process plate and process plates.

3) Robustness and simplicity: robust machine and easy to use. User friendly and simple design to avoid human error.

4) Worldwide top class components and parts supplied by international well known suppliers from Japan, USA, and Germany

5) Long lifetime and warranty of parts: laser diodes lifetime at more than 10,000 imaging hours. (approximately 20,0000 plates)

6) Long warranty of the machine: 3 years warranty (free replacement of all parts)

Low Cost of Parts: after 3 year warranty, very low cost of parts. for example, laser diode at US$250 per piece.

7) Guaranteed Service: installation and training conducted by technical engineer from factory, ensuring best setup and training to be achieved. Regular remote maintenance to be conducted every 2 month. Proactively revisit by engineers to be conducted. 7x24 hours service response.

8) Proven Worldwide market leader: (Some highlights installations)

Over 6000 units installed worldwide over past 10 years

USA and Canada: Over 50 units in USA and Canada in last 3 years by leading US press manufacturer.

Turkey: 35 units installed in Turkey by Esen Graphics

Installations in other countries UK,Italy,Spain,Hungary,Russia,Mexico,Brazil,Colombia,Ecuador,South Africa,Nigeria and etc.

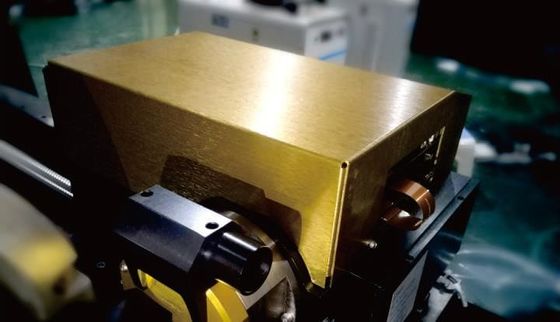

Use light valve device to divide a laser beam generated from single-source laser into 256 channels of small laser beams with even energy and its exposure screen dots are highly consistent.

Higher efficiency, lower loss-Quick plate making with 256 channels of small laser beams, output speed doubled while drum speed only 20%-50% of the conventional.

The square screen dot with sharp edge feature makes the image clearer, 10 times more accurate than 200lpi AM screening and the color saturation is increased by over 21%.

Our Factory

Our Partners and Customers

FAQ:

1. What are your main products ?

EcooGraphix is a leading and professional supplier for the Offset Prepress solution, and can also supply the Printing Materials and Postpress Packing Equipment with reliable quality and good price.

Our main products are the Prepress 4up and 8up Online/Offline Thermal CTP , CTCP , VLF CTP and CTCP, Flexo CTP , Processor , Offset Plates ,inks , blankets , postpress Packing equipments and so on.

2. Where is your factory ?

Our CTP machine factory is located in Hangzhou city , which is about 1.5 hour by train from Shanghai.

You are warmly welcomed to visit our factory!

3. What is your warranty for the CTPs ?

Three years' Laser Head and main spare parts for the CTPs, One year for the Processor.

If the customer uses Ecoographix CTP plate with the CTP machine, we will provide the Lifetime Warranty and technical support!

4. What is the Lead Time?

Usually 10-30 days, and we will try our best to meet your demands.

5. Can you also supply the Workflow and RIP?

Yes, we can provide the Workflow Brain New and RIP Compose V12.

6. What about the Installation and after-sales technical support?

Our engineer can go to help the installation and provide the necessary training. The buyer should take the round air plane tickets and service charge and the local accommodation cost. Any problems or questions,we will be at your disposal 7x24 hours.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!