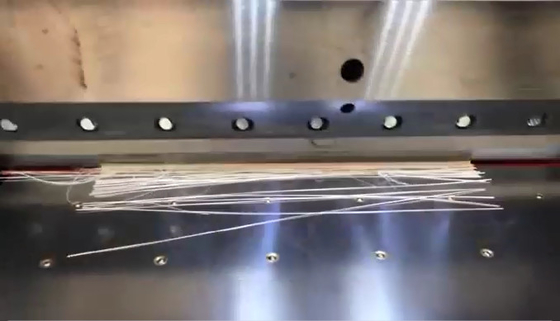

Paper Cutting Machine For Thin Materials Like Plastic, Film, Leather

→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→

Description

1. Usage:

Program Control Paper Cutting Machine is used to cut the printing paper of various kinds, paper products, plastic, thin film, leather, slice of non-ferrous metal,etc.

2. Computer:

it adopts 10 inch touch screen, color liquid crystal touch screen. It is equipped with imported whole set computer controlling system. The computer can do self-diagnose while malfunction and do self-protection while wrong operation.

3. Double Hydraulic Device:

the hydraulic system adopts the Germany advanced technology. Equipped with combined hydraulic valve, double hydraulic controlling structure, it approves hydraulic device greatly. The hydraulic device pass CE certificate.

4. Double Guide Device:

the paper pusher adopts double imported linear guide and roller ball screw, which can prolong the machine use life, and can bear the high speed paper delivering.

5. Photo Cell:

it is equipped with a photo cell safety protection device.

6. Over Load Protection Device:

convenient knife changing device.

7. Worktable Chrome Treatment:

the worktable and side board surface are all adopted chrome treatment to improve the precision and quality of the machine.

8. Air Ball:

air balls are installed in the worktable. The paper sending work will be easy and a ccurate.

9. Cutting Controller:

both of the user's hands operate the machine. It can cut paper in one time.

10. Electronic Knife Lock:

when the machine is malfunction, the electronic knife lock will lock the knife, and the machine will stop cutting to protect safety.

11. Main Electric Device

are imported from Germany, French, Japan, etc.

→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→

Specification

Paper Cutting Machine

| Specification |

Units |

ECOO1150DH-10 |

| Max. Cutting Width |

cm/inch |

115/45.3 |

| Max. Cutting Length |

cm/inch |

116/45.7 |

| Max. Cutting Height |

cm/inch |

16.5/6.5 |

| Width Of Machine |

With Sidetable |

cm |

267 |

| Without Sidetable |

cm |

237 |

| Main Motor |

kw |

4 |

| Weight |

kg |

3300 |

| Voltage |

V |

365-395 |

| Cutting Speed |

cycles/min |

45 |

| Packing Size |

L*W*H(cm) |

260*154*203 |

| Total Width Of Machine |

cm |

267 |

| Total Length Of Machine |

cm |

261 |

| Total Height Of Machine |

cm |

163 |

| The Length Of Side Table |

cm |

70 |

| The Width Of Groundsill Of Machine Foot |

cm |

60 |

| Clamp Pressure |

Min. |

N |

200 |

| Max. |

N |

40000 |

| Knife Thickness |

cm |

139x16x1.37 |

| Grinding Reserve |

cm |

6 |

| Min. Cut |

Without False Clamp |

cm/inch |

3/1.2 |

| With False Clamp |

cm/inch |

10/3.9 |

| Cutting Speed |

cycles/min |

45 |

→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→

Configuration

| No. |

Configuration |

Brand |

Model |

| 1 |

Display screen |

AU |

Taiwan |

| 2 |

Computer |

10" touch screen with keyboard(Movesun) |

Shanghai |

| 3 |

Motherboard chipset |

AMD |

America |

| 4 |

Cast |

HT250 |

HUOLONG |

| 5 |

Locating movement motor |

FUJI |

Japan |

| 6 |

Feed screw |

TBI |

Taiwan |

| 7 |

Guide |

TBI |

Taiwan |

| 8 |

Worktable |

HT250 |

HUOLONG NO.1 |

| 9 |

Bearing |

NSK |

Japan |

| 10 |

Triangle belt |

Jin huli |

China |

| 11 |

Transducer |

HJB |

China |

| 12 |

Switch |

Schneider |

French |

| 13 |

Locating switch |

Panasonic |

Japan |

| 14 |

Air pump |

Shenshen |

China |

| 15 |

Electrical |

Schneider/Omron |

French/Japan |

| 16 |

Encoder |

CCFIRST |

China |

| 17 |

Photo cell |

ZH |

SHANGHAI |

| 18 |

Proportion valve |

ATOS |

Italy |

| 19 |

Sealing ring |

NO K |

JAPAN |

| 20 |

Hydraulic pump |

Yong ling |

China |

| 21 |

Electronic knife lock |

Dapeng |

China |

| 22 |

Knife |

IKS |

Shanghai |

| 23 |

Main motor |

LB |

China |

| 24 |

Overflow valve |

ATOS |

Italy |

→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→

Producing And Packaging

From producing to delivery, we make every details very carefully to guarantee the good product quality and service to customers.

→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→

Certificates

→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→

FAQ

|

Q1: What are your main products ?

A: Our main products are the Prepress 4up and 8up Online/Offline Thermal CTP, CTCP, VLF CTP, Flexo CTP, Processor, Offset Plates, Offset Inks, Offset Printing Blankets, Postpress Packing Equipment and so on.

You can get the equipment and consumables all in one and no worry about the after-sales service from our company.

|

|

Q2: Where is your factory ?

A: Our CTP processor machine factory is in Shanghai, you are warmly welcome to visit our factory!

|

|

Q3: How long is the lead time ?

A: The lead time is normally 30 days. We can accelerate for emergency cases.

|

|

Q4: Is there any certification for your machine ?

A: Yes, all our machines have been certified by SGS and CE.

|

|

Q5: How long is the warranty period ?

A: EcooGraphix guarantees 1 year of warranty for laser head and spare parts.

|

|

Q6: What is your normal payment term ?

A: Normally, 30% TT deposit, 70% before shipping, or LC at sight.

|

|

Q7: What about the installation and after-sales technician support ?

A: Our engineer can go to help the installation and provide the necessary training. The buyer should take the round air plane tickets, service charge and the local accommodation cost. Any problems or questions, we will be at your disposal 7x24 hours. Among our large amount of CTP installations worldwide, there are also many end users(printers) who have purchased the CTP products from EcooGraphix China directly and EcooGraphix technical service team support these installations remotely with regular onsite visits.

These end users printers all run the CTP systems with full satisfaction due to our robust quality, seamless remote service, thorough training and maintanence. If you are a printer who is considering purchasing directly from EcooGraphix China, there is no hassle on installations, training and after sales service. We guarantee your satisfaction.

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!