◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷

1060x760mm 7000S/H Automatic Hot Foil Stamping Die Cutter

◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷

* * • Brief Introduction • * *

DDS106 automatic hot stamping foil die cutting machines can work on hologram stamping and other special stamping, the customers who want the high end product with good stamping result choose this model.

◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷

* * • Specifications • * *

Model ECOO-DDS106

Max. Sheet Size(mm) 1060x760

Min. Sheet Size(mm) 430x350

Max. Die Cutting Size(mm) 1060x746

Max. Stamping Size(mm) 1020x660

Height Of Cutting Rules(mm) 23.8

Max. Pressure(N) 250x104

Stock Range Min. Sheet 175g/m²; Cardboard 157-2000g/m²; E, B flute

Min. Gripper Margin(mm) 9

Max. Machine Speed(s/h) 7000

Max. Stamping Speed(s/h) 7000

Longitudinal Feeding Shafts 4 (Optional 6)

Transversal Feeding Shafts 2

Feeding Pile Height(mm) 1400

Delivery Pile Height(mm) 1100

Electric Heating System 12 zones

Min. Foil Width(mm) 20

Foil Reel Core(mm) 25(1") 76(3")

Rated Power(kw) 50

Air Supply 0.8-1.0 MPa, ≥ 0.6m3/min

Overall Dimension(mm) 5850x4600x2280

Weight Of Machine(kg) 20000

| Model |

ECOO-DDS106 |

| Max. Sheet Size(mm) |

1060x760 |

| Min. Sheet Size(mm) |

430x350 |

| Max. Die Cutting Size(mm) |

1060x746 |

| Max. Stamping Size(mm) |

1020x660 |

| Height Of Cutting Rules(mm) |

23.8 |

| Max. Pressure(N) |

250x104 |

| Stock Range |

Min. Sheet 175g/m²; Cardboard 157-2000g/m²; E, B flute |

| Min. Gripper Margin(mm) |

9 |

| Max. Machine Speed(s/h) |

7000 |

| Max. Stamping Speed(s/h) |

7000 |

| Longitudinal Feeding Shafts |

4 (Optional 6) |

| Transversal Feeding Shafts |

2 |

| Feeding Pile Height(mm) |

1400 |

| Delivery Pile Height(mm) |

1100 |

| Electric Heating System |

12 zones |

| Min. Foil Width(mm) |

20 |

| Foil Reel Core(mm) |

25(1") 76(3") |

| Rated Power(kw) |

50 |

| Air Supply |

0.8-1.0 MPa, ≥ 0.6m3/min |

| Overall Dimension(mm) |

5850x4600x2280 |

| Weight Of Machine(kg) |

20000 |

◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷

* * • Feeder • * *

★. Conjugate cam mechanism for sheets feeding

☆. Adjustable suckers head angles to handle different kinds of materials

♦. Non stop sheet loading

♥. Automatic feeding table up and down

♠. Manual adjust on front registration synchronized with auto running

♣. Micro adjustable side lays with pull/push in one

△. Side lays with photoelectric detection

▽. 4 Independent front lays with photoelectric detection

○. Accurate reposition of the distance between the platens, less than 0.01mm

★. Digital pressure display

☆. Center line system

♦. 7 Specially hardened alloy gripper bars, each bar is adjustable to secure accuracy

♥. Tri-point gripper bar registration provides high accuracy in round registrations

♠. Pretensioned main chain with lower extension

♣. Cam mechanism for gripper bar drive assures smooth and accuracy running

△. Torque clutch protects index box from concussion on gripper bar

▽. Cam mechanism for gripper finger control assures precise sheet registration

○. Specially designed dwell function for stamping

★. Automatic and timing lubrication

◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷

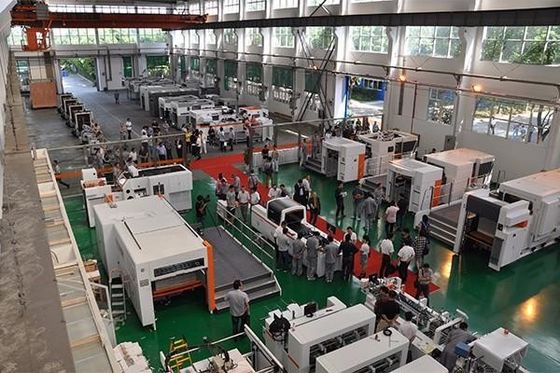

* * • Producing And Packaging • * *

From producing to delivery, we make every details very carefully to guarantee the good product quality and service to customers.

◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷

* * • Certificates • * *

◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷ ◀ ▶ ◁ ▷

* * • FAQ • * *

Q1: What are your main products ?

A: Our main products are the Prepress 4up and 8up Online/Offline Thermal CTP, CTCP, VLF CTP, Flexo CTP, Processor, Offset Plates, Offset Inks, Offset Printing Blankets, Postpress Packing Equipment and so on.

You can get the equipment and consumables all in one and no worry about the after-sales service from our company.

Q2: Where is your factory ?

A: Our CTP processor machine factory is in Shanghai, you are warmly welcome to visit our factory!

Q3: Is there any certification for your CTP processor ?

A: Yes, all our machines have been certified by SGS and CE.

Q4: Can you also supply the Workflow and RIP ?

A: Yes, we can provide the Workflow Brainnew and RIP Compose V12.

Q5: What about the installation and after-sales technician support ?

A: Our engineer can go to help the installation and provide the necessary training. The buyer should take the round air plane tickets, service charge and the local accommodation cost. Any problems or questions, we will be at your disposal 7x24 hours. Among our large amount of CTP installations worldwide, there are also many end users(printers) who have purchased the CTP products from EcooGraphix China directly and EcooGraphix technical service team support these installations remotely with regular onsite visits.

These end users printers all run the CTP systems with full satisfaction due to our robust quality, seamless remote service, thorough training and maintanence. If you are a printer who is considering purchasing directly from EcooGraphix China, there is no hassle on installations, training and after sales service. We guarantee your satisfaction.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!