Solvent Water Wash Polymer Flexo CTP Printing Plate 1.14mm to 3.94mm

Flexographic printing is one of the most commonly used printing methods at present, because traditional printing methods have their own characteristics.

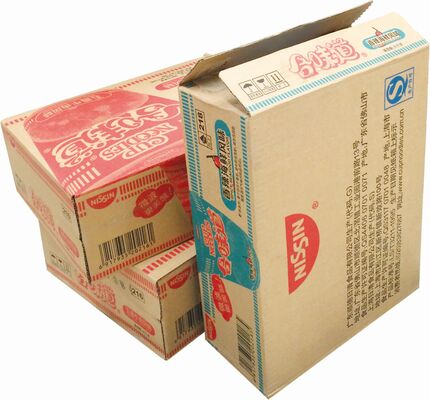

Flexo printing has achieved considerable development in recent years. The water-based ink used in flexographic printing is an environmentally friendly printing method that does not cause a lot of pollution like gravure printing. Relatively speaking, the cost of flexo printing is relatively low, and the printing volume is large. It is suitable for printing on sheet paper and roll materials of different materials. It is most suitable for packaging printing, various labels and large-area substrates.

EcooGraphix is a professional flexo plate making productions solution supplier in China for more than 10years now. We can provide different plate making Flexo CTP and flexo plate processing equipment, and the flexo plates with 3years warranty.

Features:

Compared with traditional offset printing, gravure printing and embossed printing, flexographic printing has the following characteristics:

1. High production efficiency. Flexographic printing uses roll materials, which can not only realize double-sided printing of printing materials, but also complete online glazing, hot stamping, die-cutting, waste discharge, rewinding and other tasks;

2. The range of printing materials is relatively wide, such as paper, plastic film, aluminum foil, self-adhesive paper, etc.;

3. The print quality is good, and the printing accuracy can reach the number of printing lines of offset printing, which is especially suitable for the requirements of packaging printing;

4. Use new water-based inks and solvent-based inks, which fully comply with green and environmentally friendly printing requirements and can also meet the requirements of food packaging;

5. Shorten the production cycle, save materials and manpower, reduce production costs, and improve efficiency.

Traditional analog flexo plate process

Computer document - digital proofing or blue paper pattern → adjust the corresponding dot expansion compensation curve according to the printed fingerprint - the phototypesetter outputs the negative image film - the printing machine exposes the back of the traditional plate - vacuums the front of the plate to the film and makes the main exposure of the film surface - removes the film and puts the plate into the plate washer, washes the plate with solution - plate drying and UVA, UVC and other post-processing - checks the size and modify the edge - completes the traditional flexographic printing plate production.

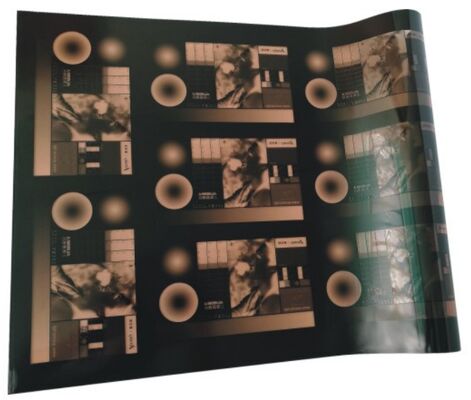

Digital CTP flexo plate making process

Computer document - digital proofing or blue paper pattern → exposure of the back of the digital plate by the printing machine - main exposure of the digital plate on the front of the flexo CTP - put into the traditional plate washing machine, wash the plate with solution - drying of the plate and UVA, UVC and other post-processing → check to complete the digital flexographic plate production.

Specification of Flexo CTP

| Model |

ECOO-FL4835S |

ECOO-FL4835F |

| Exposing Mothod |

External Drum |

| Imaging System |

1064nm fiber laser device (H256 heads) |

| Throughput |

3 sqm/hour at 5080 dpi |

5 sqm/hour at 5080 dpi |

| |

48*35 inch, about 20 minutes |

48*35 inch, about 12 minutes |

| Exposing Size |

Max.size 1200*1020mm, min. Size 200*200mm |

| Media Type |

Dry ablation film, Digital water washing letterpress plate. Digital water washing flexo plate, Digital solvent washing flexo plate |

| Plate Thickness |

0.14mm to 6.35mm |

| Resolution |

5080DPI (compatible with 2540DPI) , can extend to support 10160DPI |

| Plate Loading |

Automatic/Manual plate loading |

| Net Weight |

1500kg |

Machine Size

(WxLxH)mm |

1974*1750*1537mm (L*W*H) |

| Power Supply |

Three phase voltage: 380V, Max. Power (peak value) 16 kw |

Operation

Environment |

recommended:15-30℃, Max.21-25℃, humidity:40-70% |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!