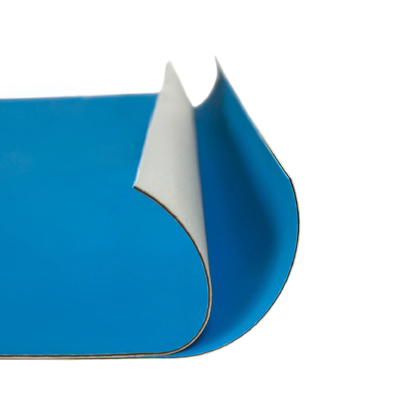

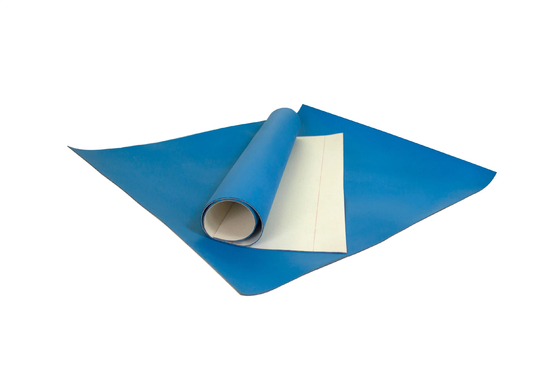

Printing Rubber Blanket is widely used in offset printing.

It is made of three layers of rubber and fabric, which makes it highly durable and resistant to wear and tear.

The hardness of the blanket is between 76-80, with tensile strength more than 80 N/mm.

It is suitable for speed range of 8,000-12,000 prints/hour, making it ideal for high-speed offset printing.

With its excellent construction and durability, this Printing Rubber Blanket is the perfect choice for offset printing.

1. Where does a blanket use in printing?

See the beside image. The blanket is used to cover the blanket cylinder (the intermediate cylinder) in each color unit within printing machine.

2. How does it work?

Simply speaking, the blanket is to transfer the image from plate onto paper. The image is "offset" onto the blanket and then to paper. The blanket created a smoother image on most types of paper and canprint on rough or heavy stocks as well as other media. Most offset presses use this lithographic method.

3. The Final products:

It is suitable for printing of coated papers, carton boards and the like. So the finish products of whole offset printing would be carton, coated paper, newspaper, magazine, and so on.

4. Maintenance:

-Clean the blanket with fast volatile organic solvents.

-Clean rolls when ink color changing or refilling.

-Release the blanket off the cylinder when the printing machine stopped for a long time.

-New blankets should be stored in dry and cool place covered with dark layer.

Specification

Application:

Strong universality; Appropriate to dot and word printing;

Speed:

about 15000 prints/hour

Construction:

4/3ply fabric

Thickness:

1.97/1.70±0.02mm

Color:

Blue/Green

Compressible layer:

Microspheres

Surface:

Micro-ground and polished

Roughness:

0.80-1.0μm

Hardness:

76-80 Shore A

Elongation:

≤ 1.0%

Tensile strength:

≥ 85

Characteristic: Moderate compressibility avoids moving image of machine and reduces the edge marking. Wide-ranging print. Prefer to carton print and full mold print.

Producing And Packaing

The printing rubber blanket is carefully wrapped in a quality corrugated paper and packed in a strong cardboard box.

It is then shipped in a secure and safe manner to ensure the product reaches its destination in perfect condition.

FAQ

Q1: Do you offer free sample? How long is the sample time of the shipping? Does the sample fee can be returned?

Since blanket is high value, we did not offer free sample. But we can offer favorable discount. It will take 5 days to prepare sample. If you place bulk order after sample testing, we will refund the sample fee and courier cost.

Q2: About the sample how to calculate the cost of transportation?

The freight depends on weight, packing size and your country or province region,etc.

Q3: How long can I expect to get the sample?

The sample will be ready for delivery in 3-5 days and will be sent via international express such as DHL, UPS, TNT, FEDEX and would be arrived within 3-5 days.

Q4: How about lead time?

The lead time for sample order is 5 days and for bulk order is normally 20 days. If there is special requirement, lead time will be negotiated on detailed case.

Q5. Payment term

Normally, 30% deposit, 70% before shipping.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!