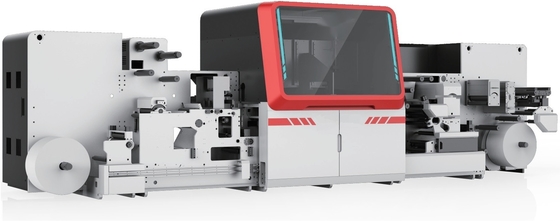

Roll To Roll Cost-effective Digital Printer For Label Printing

☏ Benefit

☆. Highly flexible feeding system, suitable for all materials for 80-330mm wide label printing.

★. Imported high-precision industrial print head has higher fire ignition frequency and service life.

♣. The patch tracking electronic eye achieves accurate secondary surprint, comprehensively solves the problem of printing registration.

♦. Broad color gamut UV ink, vivid colors, with color management system, can accurately restore the Pantone database colors.

♥. Resolution up to 600X1200 dpi.

✉ Main Technical Data

☎ Specifications

Label Printing Machine

Model

Ecoo Label Modular 330

Printing Technology

Piezoelectric inkjet

Print Method

Roll to roll, one-side

Color Configuration

Support up to 8 colors

Number Of Channels

8

Maximum Speed

50 m/min(CMYK); 25 m/min(CMYK+W)

Resolution

600x600 dpi/ 600 x1200 dpi

Ink Type

UV ink

Curing Method

UV LED + mercury lamp

Media Width

150-350 mm

Maximum Print Width

324 mm

Media Thickness

50-400 μm

Media Type

PET, BOPP, PE, BOPA PP, coated paper, synthetic paper, art paper, etc

Maximum Media Roll Diameter

700 mm

Power Supply

380 V

Power

30 kw

Compressed Air

> 6.5 MPa

Air Consumption

> 10 L/min

Operating Environment

Temperature: 20ºC-27ºC, Humidity: 40%-70% relative humidity

Skew Adjustment System

yes

Electrostatic Dust Removal

yes

Water Cooling System

yes

Coating Unit

optional

Digital Varnishing

optional

Cold Foil Stamping

optional

Hot Foil Stamping

optional

Visual Inspection

optional

☺ Features

♥. Highly flexible feeding system

Feeding unit for inkjet digital printing system, with high flexibility, suitable for many materials for 150-330mm wide label printing: film(PET, BOPP, PE, BOPA), label stock(PE label), pre-pressed materials(PET, ALU, PE), paper, among others.

♠. Stable and high-speed printing unit

Imported high-precision industrial print head has higher fire ignition frequency and service life, resolution up to 600*1200 dpi, guaranteed excellent print quality. The patch tracking electronic eye achieves accurate secondary surprint, comprehensively solves the problem of printing registration, and makes the printed matter more aesthetic.

♦. High quality UV eco-friendly Ink

Benefit from the excellent ink formula, our UV eco-friendly ink can still achieve excellent stability while ensuring environmental protection. Broad color gamut UV ink, vivid colors, with color management system, can accurately restore the Pantone database colors.

♣. Unique print head control system

Each print head has its own board to control, makes printhead printing more efficiency and easier to maintain.

♥. Automatic winding and unwinding system

Effectively prevent the substrate from shifting, ensure the orderliness of the winding and unwinding system and achieve non-stop production for a long time.High linkage winding system, fully automated, to maximize automated production.

✈ Producing And Packaging

From producing to delivery, we make every details very carefully to guarantee the good product quality and service to customers.

✌ Certificates

❤ FAQ

Q1: What are your main products ?

A: Our main products are the Prepress 4up and 8up Online/Offline Thermal CTP, CTCP, VLF CTP, Flexo CTP, Processor, Offset Plates, Offset Inks, Offset Printing Blankets, Postpress Packing Equipment and so on.

You can get the equipment and consumables all in one and no worry about the after-sales service from our company.

Q2: Where is your factory ?

A: Our CTP processor machine factory is in Shanghai, you are warmly welcome to visit our factory!

Q3: What is your warranty for the CTPs ?

A: Three years' laser head and main spare parts for the CTPs, one year for the processor.

If the customer use EcooGraphix CTP plate with the CTP machine, we will provide the Lifetime Warranty.

Q4: Can you also supply the Workflow and RIP ?

A: Yes, we can provide the Workflow Brainnew and RIP Compose V12.

Q5: What about the installation and after-sales technician support ?

A: Our engineer can go to help the installation and provide the necessary training. The buyer should take the round air plane tickets, service charge and the local accommodation cost. Any problems or questions, we will be at your disposal 7x24 hours. Among our large amount of CTP installations worldwide, there are also many end users(printers) who have purchased the CTP products from EcooGraphix China directly and EcooGraphix technical service team support these installations remotely with regular onsite visits.

These end users printers all run the CTP systems with full satisfaction due to our robust quality, seamless remote service, thorough training and maintanence. If you are a printer who is considering purchasing directly from EcooGraphix China, there is no hassle on installations, training and after sales service. We guarantee your satisfaction.

Video ☞ https://youtu.be/g5Ohy64Wzt4?si=9o0GhZD3Vjk-yzpE

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!