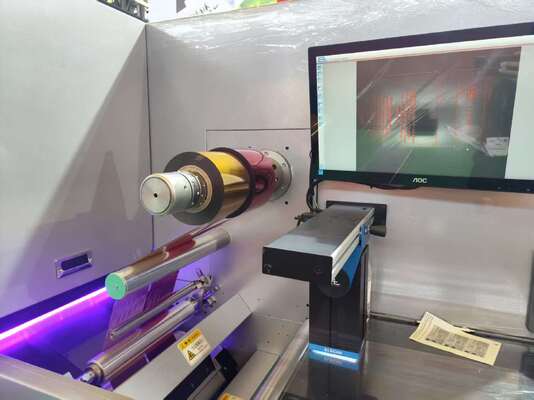

Digital Label UV Varnish Printing and Foil Stamping Machine

Label printing using hot or cold foil stamping technology has made great progress in recent years. For example, laser, anodized aluminum, hot stamping or UV LED cold stamping make the product beautiful, colorful and saturated, making it difficult to counterfeit. In particular, the hot stamping process of cigarettes is very demanding and must have certain anti-counterfeiting properties.

Therefore, if you want to improve the quality of label printing, you must also improve the smoothness, gloss, and anti-counterfeiting performance of the product to ensure the consumption intensity and grade of the product.

Today's cold foil technology continues to develop, and many excellent label printing equipment can make label printing even more powerful. For example, high-end red wine labels, beverage labels, cosmetic packaging, and gift box labels all use hot stamping technology skillfully.

EcooSpark is the first digital roll label embelishment machine in China from 2018,with many installations worldwide. Simple design, robustness, reliability and state of art quality are core strengths.

This machine can do UV spot varnishing, cold foil stamping, braille printing ,3D embossing ,lamination and etcs,

by KM print head and digital LED UV Inkjet technology.

Features:

1)Full Sets of Mitsubishi servers;

2)HeFeng Corona Treatment;

3)Web guide and Monitoring System: E+L;

4) Full Led-UV curing system;

5) Printing Software: GIS UK;

6)Auto Cleaning System;

7) KM 1024i print head;

8) Multiple sensors for tention control.

There are 288mm, 330 mm and 430 mm model optional (printing width).

Most of our machines are used for about 5years now with no trouble,customers are very pleased with the machine stable and perfect performance.

We can provide 3 years'warranty for the machine and print heads. Prices and trading terms are negotiable.

Specification:

| Model EcooSpark |

| Printing Technology |

UV Piezo DoD(drop on demand)-inkjet |

|

| Resolution |

up to 1440*360 dpi |

|

| Printing speed |

10m/min - 60m/min(depend on polymer layer thickness) |

|

| Variable Image system |

PDF, optimized PDF, Optional barcode system |

|

| Supported image standards |

PDF,PDF/VT,TIFF, JPEG, BMP & other data base files |

|

| Substrates |

Offset, Digital, Plastics, Laminated and coated substrates |

|

| Printing image width |

288mm (extendable to 320 mm) * 10 m (Length) |

|

| Polymer |

WB-DS-Clear Polymer |

|

| Polymer layer thickness |

From 10 up to 180 microns |

|

| Ink curing |

Inter UV-LED Pre-curing/Full curing by UV-LED |

|

| Unwinder diameter |

Max. 700mm, Core 76mm |

|

| Rewinder diameter |

Max. 700mm, Core 76mm |

|

| Substrates thickness |

30-400 micro |

|

| Substrates width |

Max 330mm |

|

| Press with Foil station |

Machine dimensions (LxHxW) 3500mmx1900mmx1800mm |

|

| Operating environment |

Temperature: 15℃-30℃, Humidity: 40%-80% relative humidity |

|

|

Electrical requirements

|

Voltage: 3x380, ±5% 3 phases +G+N ; Frequency: 50/60 Hz

Current: Avg. 25 Amps

|

|

| Weight |

2800kg |

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!